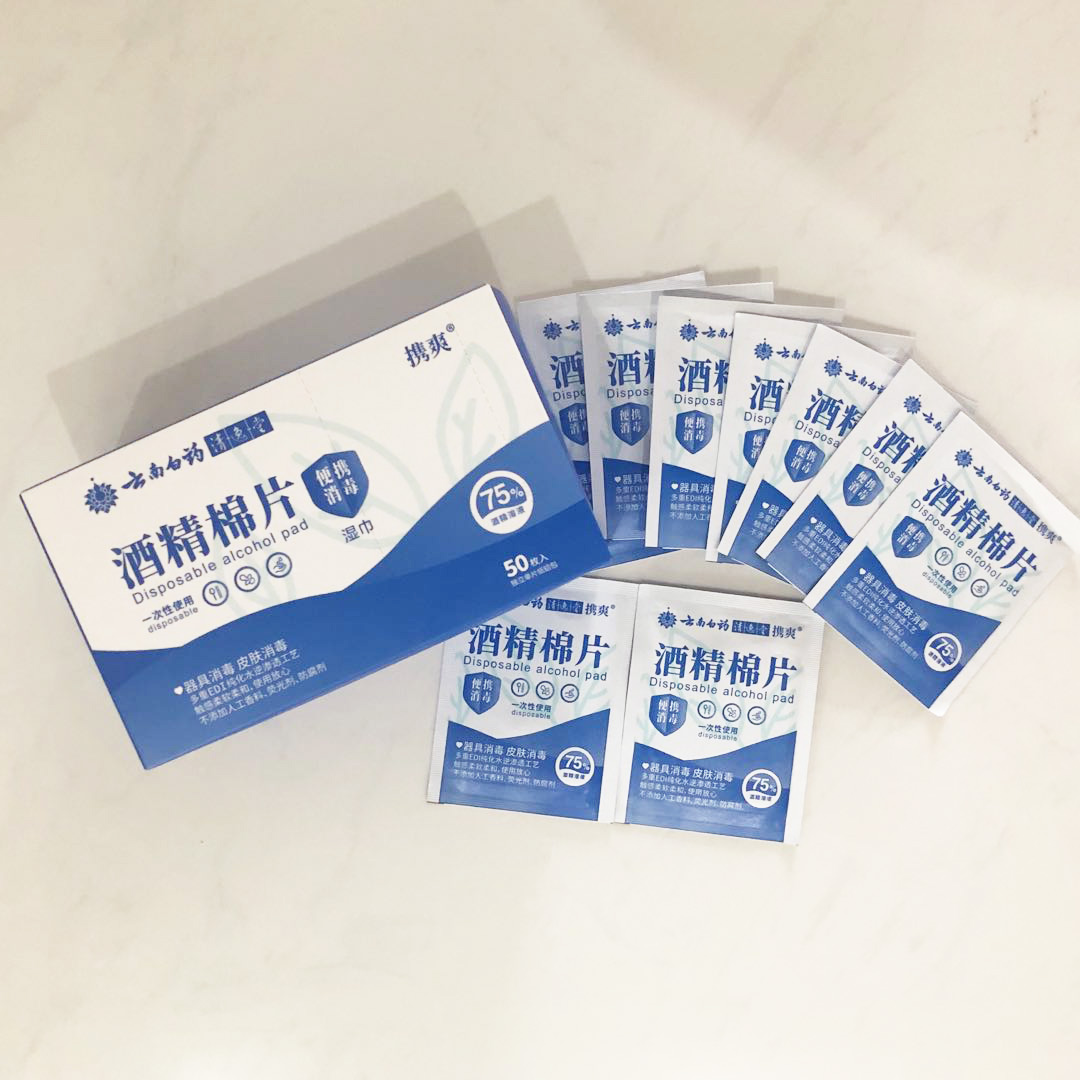

This is the fully automatic alcohol pad production line .

Processing:material—splitting —folding— moisture—cutting—pile counting— transport —packing

The machine speed :60-70 boxes/min

Longitudinal Z fold, W folding,and the V fold. The width and the length of the tissue can be adjusted on the machine in the range. ( The length adjusted by PLC)

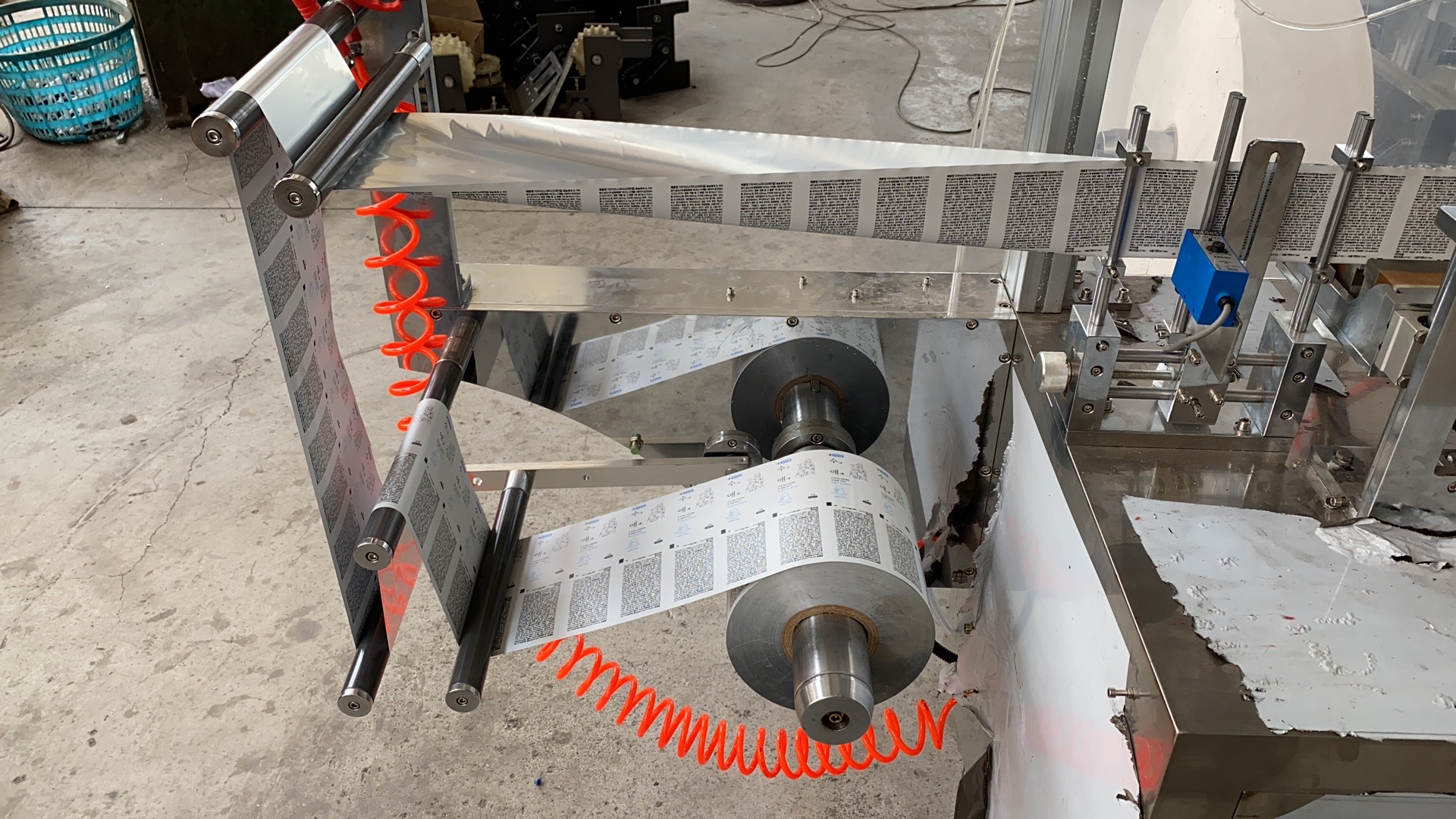

Pull tension adjuster

Auto change the spun lace non woven.

Short cut length can be adjusted.

Lotion supplying system, including two tank with continuously agitators mixing, recycle unit, lotion applicator sucking, liquid from the tank and spraying liquid to the product continuously with adjustable amount.

Liquid come out from holes, more or less liquid can be controlled by the machine, similar as water faucet control. It is pillow type packing, 4 temperature controlled system for the sealing system.

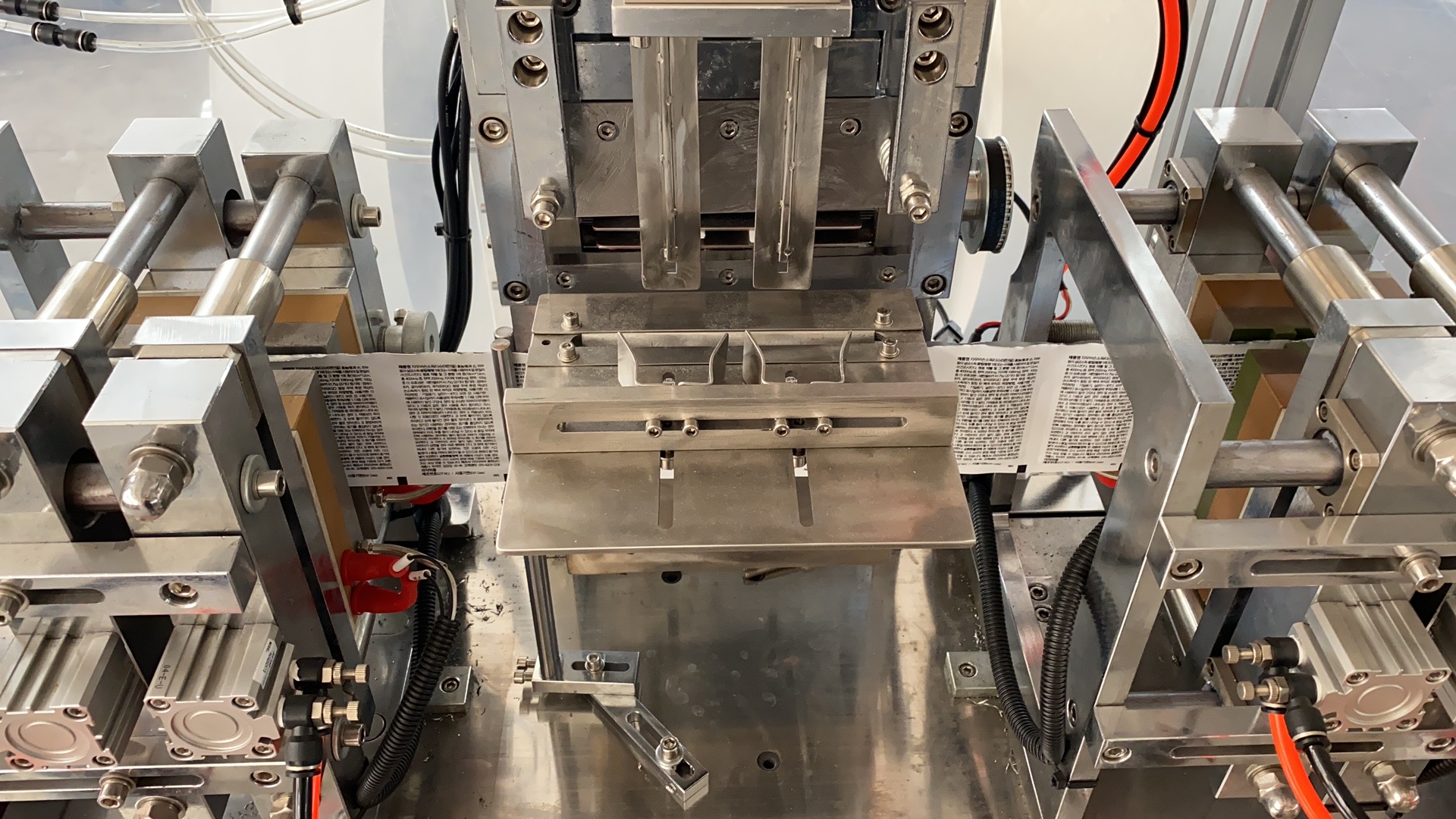

Cycle hole

Insert corner

Date printing system: such as production date, and Exp date printing, Ink printing type,.

Bag film unwinding, auto unwinder with tension control. Punching system for the packing film. (open the window for the package).

Label supply, adopted auto unwinder with tension control. Double label system.

Full transfer system, from the folding part to packing part, it can controlled by sensor. Less labor required.

Bag forming applicator, bag film wrap the stacked products, the size can be adjusted. If requires size are big difference, the unit much be changed.

Bagger has individual control system with operate interface, which is connected to main machine for control system.