1.Extremely efficient, high power, low noise, easy to maintain and has a long life span.

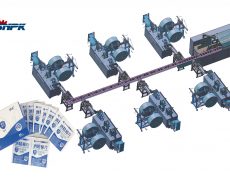

2.Roller heat sealing, four side sealing, high speed and multi-line packing, and with bags coming smoothly and fine, high packing efficiency.

3.Easy to adjust, precise in measurement, requires a simple procedure for pouch length adjustment without changing the mould. Functions can be regulated for longitudinal sealing, transverse sealing, filling, notch cutting, longitudinal cutting, fracture line making and transverse cutting with the advanced technology for our man-machine interface.

4.Famous servo motor driver is adopted, high-performance PLC pouch length can be setup directly at the touch screen, at the same time longitudinal sealing and transverse sealing be able to auto in-phase tracking. It saves more time and material compare with mechanical transmission, and with bag pulling smoother and even easier to adjust.

5.Accuracy in page correcting, automatic counting, and photoelectric tracking system is adopted to ensure the automatic correcting the double face printing design on packing bags, precise in counting.

6.It has reliable performance, convenient to operate and super automatic. A PLC is used for automatic controlling and frequency changer is for step-less speed adjusting.

7.Applicable to a wide using: suitable for most of the complex film packing materials

| Main technological parameter: | |||

| Bag length | 50-300 mm | ||

| Bag width | 40-105mm | ||

| Packing dosage | 5-105 ML | ||

| Applicable film | 150-400 bags/min | ||

| Max film width | 900 mm | ||

| Mac film diameter | 300mm | ||

| Film core diameter | Φ75mm | ||

| G.W. | 150Kg | ||

| Package size | 1650*1500*2200 | ||

| Applicable film | PET/AL/PE, PET/PE, NY/PE, NY/AL/PE | ||