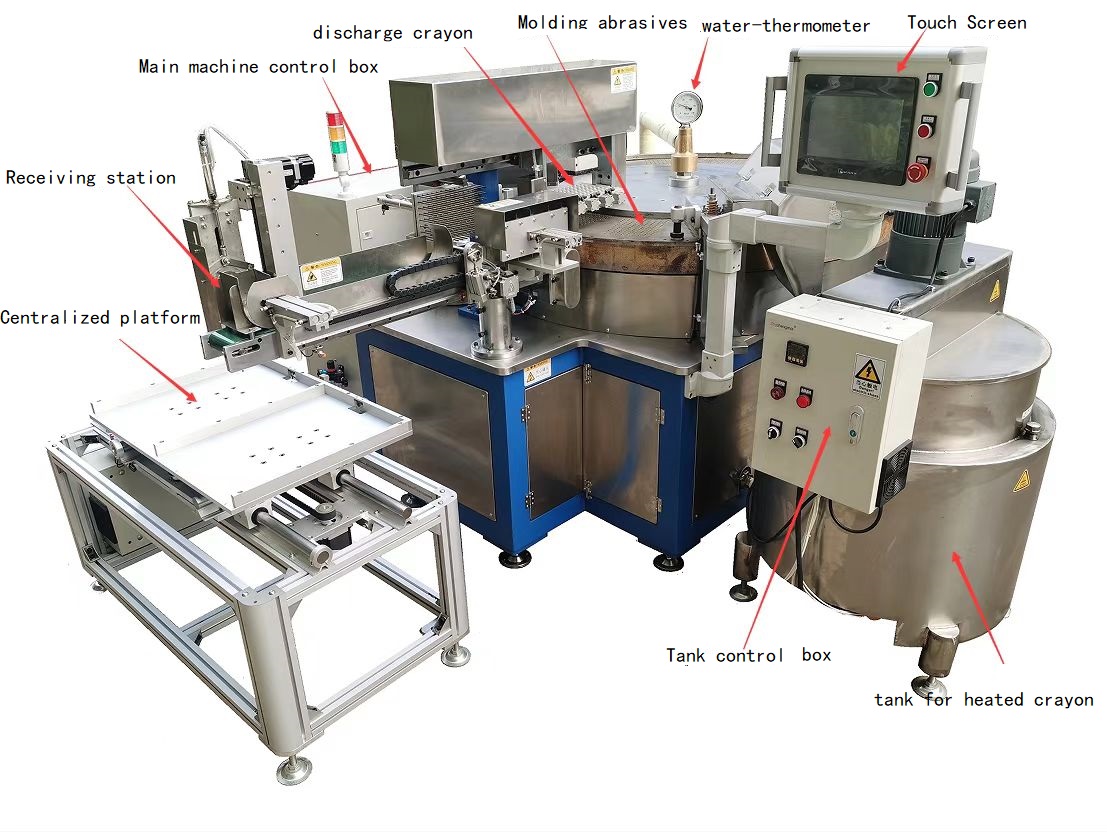

Technical data

Main machine size: 290cm X 250cm X160cm

Power supply:220V 3 phase /380V 50/60 Hz

Machine weight: 2100 Kg Total

Power:23 Kw

Pneumatic pressure:0.3 MPa

capacity:≥18 sec/mould

Oil pressure:4.5 MPa

Crayon Diameter customized

Tank Volume:100 L-200L

Crayon length:customized

Features:

1. the whole production process: melting material, mixing, spraying demoulding agent, pumping material, filling material, cooling, shovel material return, top crayon, grasp crayon, packing;

2.heating mode: heating tube, heat conduction oil heating;

3. heating parts: barrel, feeding pipeline, feeding trough, feeding pump;

4. Mold cooling mode: one inch and a half main water pipe flows into the mold frame from the cold water outlet under the mold, and then flows out from the middle to the middle drainage outlet and drains back to the cooling tank;

5. material pot function: heating, stirring;

6. material pot capacity: 120L;

7. spray release agent: release agent after atomization spray on the thimble and die surface;

8. Material injection: prepare the material in the material trough through the material pump, and wait for the mold to rotate in place.

9. shovel material: automatically shovel the excess material back to the material pot heating;

10. Automatic crayon jacking: automatically jacking out the crayon and putting the crayon on the conveyor belt through the crayon grabbing mechanism;

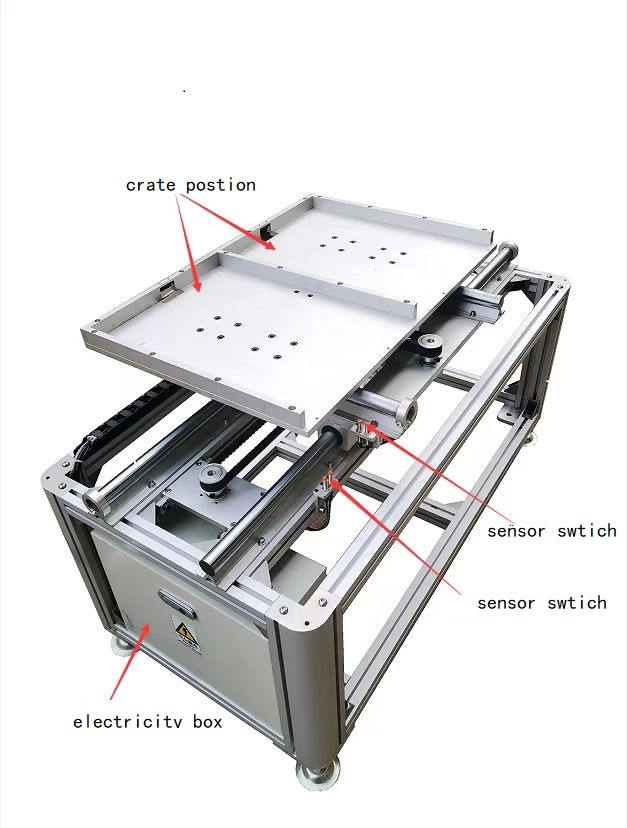

11. Automatic packing: after the manipulator, the crayons on the conveyor belt are caught in the positioning plastic frame, and the discharge is good in order and level. After filling a box, there is an alarm to change the box.

How Crayons are Made

Introduction

What are Crayons

Crayons are a popular drawing tool especially loved by children for their ease of use and vibrant colors. They are typically made of wax and can be used to create colorful artwork on various surfaces, most commonly paper. Crayons are solid sticks of color that can be applied smoothly, and they come in a wide array of colors to spark the imagination of users of all ages.

Unlike markers or paint, crayons do not require any preparation or additional tools to use, making them a convenient option for spontaneous art creation. They are also relatively mess-free, as they do not spill or splatter. The simplicity and versatility of crayons make them a staple in classrooms, homes, and art studios around the world.

Brief History of Crayons

The history of crayons dates back to ancient times when people used colored wax sticks for writing and drawing. However, the modern crayon, as we know it, began to take shape in the early 20th century. The first crayons were made by mixing charcoal and oil, but these were replaced by wax crayons that offered a wider range of colors and better handling properties.

One of the most significant developments in the history of crayons occurred when companies began to produce crayons that were safe for children to use. This was a major milestone that led to the widespread popularity of crayons in schools and homes. Over the years, crayons have evolved, with manufacturers experimenting with different formulas to improve quality and durability.

Materials Needed

Wax

The primary ingredient in crayons is wax. Paraffin wax is commonly used because of its excellent color adherence, ease of molding, and low cost. The wax is obtained by refining petroleum, which is then processed and purified to meet the standards required for crayon production. The quality of the wax plays a crucial role in determining the final quality of the crayons, including their hardness, smoothness, and melting point.

Color Pigments

Color pigments are what give crayons their vibrant hues. These pigments are finely ground powders that are mixed with the wax to create different colors. A wide variety of pigments are used, each carefully selected to achieve a specific shade. The pigments must be non-toxic and safe for use by children, as well as consistent in color quality to produce reliable and uniform crayon colors.

Other Ingredients

Besides wax and color pigments, other ingredients are added to the crayon mixture to enhance its properties. These can include stearic acid, which acts as a hardener and gives crayons their smooth texture. Some crayons may also contain chalk or calcium carbonate to improve opacity and coverage. Manufacturers may add other proprietary ingredients to create crayons with unique characteristics, such as washability or extra strength.

Crayon Manufacturing Process

Melting the Wax

The first step in making crayons is melting the wax. Large industrial vats are used to heat the paraffin wax until it becomes a clear, liquid form. The melting process must be carefully controlled to ensure that the wax reaches the correct temperature for optimal mixing with the color pigments. If the wax is not heated properly, it can affect the consistency and quality of the final product.

Adding Color Pigments

Once the wax is melted, color pigments are added to the liquid wax. This step requires precision, as the amount of pigment must be carefully measured to achieve the desired color intensity. The mixture is then stirred thoroughly to ensure that the pigment is evenly distributed throughout the wax. This homogenous mixture is essential for producing crayons with consistent color.

Molding the Crayons

After the colored wax is prepared, it is poured into crayon-shaped molds. These molds can be made of metal or other materials that can withstand the high temperatures of the molten wax. The molds are filled with the wax and then cooled to allow the crayons to solidify. The design of the mold determines the size and shape of the crayon, and it can be customized to create various types of crayons.

Cooling and Packaging

The final step in the manufacturing process is cooling and packaging. The molded crayons are first allowed to cool and harden. Once they are solid, they are removed from the molds and inspected for quality. Crayons that meet the quality standards are then wrapped with paper labels, which provide a surface to hold and also prevent the crayon from leaving marks on the user’s hands. The labeled crayons are then packaged into boxes and are ready to be shipped to stores.

Different Types of Crayons

Wax Crayons

Wax crayons are the most common type of crayons and are what most people think of when they hear the word “crayon.” They are made primarily of paraffin wax and are known for their durability and bright colors. Wax crayons are suitable for use on a variety of paper types and are a favorite among young children for coloring and drawing.

Oil Pastel Crayons

Oil pastel crayons are a type of crayon that uses a non-drying oil and wax binder to create a creamy texture that glides smoothly over surfaces. They are often used by artists for their vibrant colors and the ability to blend and layer colors effectively. Oil pastels can be used on a variety of surfaces, including paper, canvas, and wood.

Watercolor Crayons

Watercolor crayons are a unique type of crayon that can be used both dry and wet. When used dry, they function like traditional wax crayons. However, when water is applied with a brush, they create a watercolor effect on the paper. This versatility makes watercolor crayons a popular choice for artists who want to combine drawing and painting techniques.

Safety Measures in Crayon Production

Non-Toxic Materials

Ensuring the safety of crayons is of utmost importance, especially since they are frequently used by children. Manufacturers must use non-toxic materials in their crayons to prevent any health hazards. This includes selecting pigments that are free from harmful chemicals and ensuring that all other ingredients meet safety standards.

Safe Manufacturing Practices

In addition to using safe materials, crayon manufacturers must also follow safe manufacturing practices. This includes maintaining a clean and safe working environment, providing proper training for employees, and implementing quality control measures to detect and eliminate any potential safety issues with the crayons before they reach consumers.

Environmental Impact of Crayon Production

Waste Management

The production of crayons generates waste materials, including excess wax and misshapen crayons. Responsible manufacturers implement waste management practices to minimize the environmental impact of their operations. This can include recycling waste wax and defective crayons back into the production process, reducing the need for new raw materials.

Sustainable Practices

Many crayon manufacturers are moving towards more sustainable practices, such as using renewable energy sources and sourcing eco-friendly materials. Some companies offer crayons made from beeswax or soy wax, which are renewable resources. Additionally, packaging made from recycled or biodegradable materials is becoming more common, further reducing the environmental footprint of crayon production.

Fun Facts about Crayons

World’s Largest Crayon

The world’s largest crayon was made by Crayola in 2003 and is 15 feet long, weighing over 1,500 pounds. It was created using leftover crayon bits sent in by children across the United States. This giant crayon is blue, which is also one of the most popular crayon colors among children.

Most Popular Crayon Colors

While there are hundreds of crayon colors, some have become favorites over the years. Blue is consistently ranked as the most popular crayon color, followed by other classics like red, violet, and green. These colors have stood the test of time and continue to be staples in crayon boxes around the world.